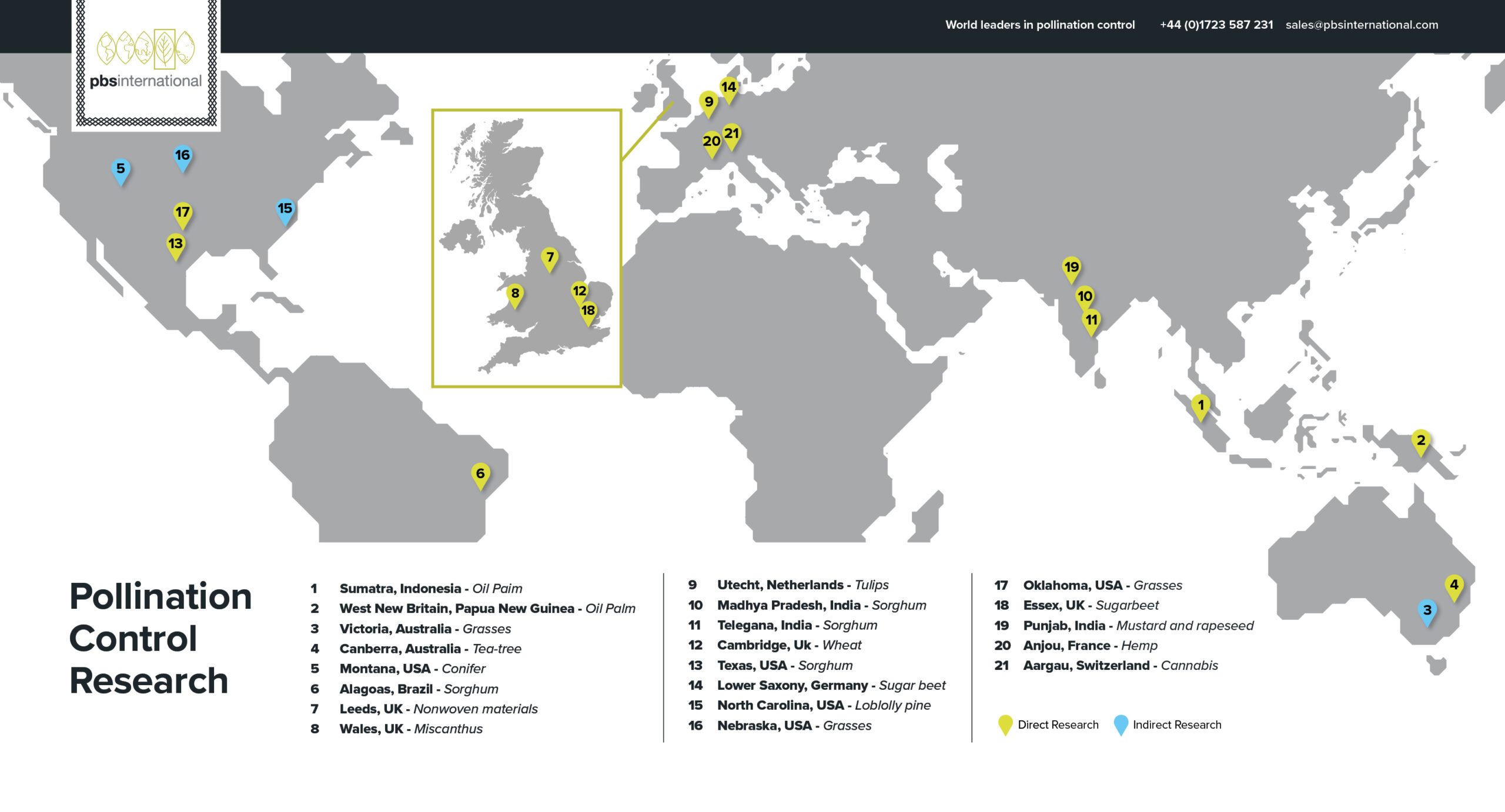

Collaborative research with our customers has been part and parcel of our R&D since the early days. Over decades, we’ve researched dozens of crop species in locations worldwide, from mustard in India to sugar beet in South East England.

Our new Research Map celebrates everything we’ve achieved so far, capturing how our products work with different crops, climates, and companies. But it all started with a flash of inspiration in a hotel room more than 60 years ago…

Click here to enlarge the map

The journey begins

In 1960, a Forestry Commission worker visiting Scarborough was cleaning his shoes one evening. A thought struck him: Could the fabric of his cleaning cloth make a pollen-proof backing for tree breeding?

He asked local manufacturer Duraweld to turn the idea into reality. By the 1980’s Johanna Senior, inspired by the forester’s curiosity, had created PBS International, a sister company to Duraweld. It focused specifically on pollination control products, an area with clear market potential. In the years since, we’ve continuously refined and improved our products through research, testing them with crops around the world in a range of climates and conditions, from the humid rainy season in India to temperate Europe and subtropical Brazil.

Our duraweb® family of materials is made by bonding randomly overlaid polyester fibres, creating an architecture that confers unique properties without using additional chemicals. They are flexible, strong and fine enough to trap all but the tiniest grains of pollen. They can stand up to a rainstorm but are permeable to air, moisture and sunlight, so when they’re made into bags and tents using duraweld® pollen-proof seams, they create an internal microclimate that’s as natural as possible.

Our manufacturing process is backed by our duratrace™ quality control system, and we are proud to be ISO 9001 certified for quality management.

Connecting plant science and non-woven technologies

Right from the beginning, we’ve been closely connected to the scientific community, undertaking peer-reviewed research to continuously develop our products. Johanna Senior set the pattern with her 1987 article Testing the Efficiency of Pollen Bag Materials.

Since then, we’ve contributed to research on how our products and materials meet our customers’ needs, with a wide variety of crops in diverse climates.

Leading our research team today is our technical manager Professor Daljit S. Virk (OBE), who brings more than 45 years of experience as a geneticist and plant breeder, university professor, Senior Research Fellow, and International Projects Coordinator. To mark the release of the Research Map, we asked Daljit and the team to pick five stand-out research papers from our catalogue of research.

Driving higher revenue from African oil palm (Elaeis guineensis)

Pollination control is critical to avoid genetic contamination in African oil palm seed production, where palms must have the right hybridisation profile to produce maximum oil yields over their 25-year lifespan. If the seeds are genetically compromised, producers may abandon them, losing $1,000 in potential revenue per seed bunch. But does the type of pollination bag influence genetic purity?

The results of our research at the Dami Oil Palm Research Station (OPRS) in Papua New Guinea make for a resounding ‘yes.’ In controlled experiments, researchers tested duraweb® pollen bags against canvas and Tyvek-style polyethylene bags across three important criteria – the presence of insects, which is connected to genetic contamination, whether the bags held their shape and resisted damage, protecting the flowers, and whether they accumulated water. Unlike the other bags, ours remained insect-free and dry inside, staying structurally intact.

Avoiding genetic contamination reaps rewards for growers: Data from the Malaysian Palm Oil Board demonstrate that seed producers using PBS bags charge an average of 17% more per seed.

Boosting seed counts in mustard (Brassica juncea) and rapeseed (Brassica napus)

Breeders of mustard and rapeseed use pollen bags to keep their stocks’ genetic makeup under control and protect flowers from damage. However, the humid, light-restricted microclimate inside standard bags creates a reduction in seed yield.

Our research with the Oilseeds Research Farms of Punjab Agricultural University (PAU) in Ludhiana, India, shows what a difference it makes when light, air and moisture can flow in and out of the pollen bag. Self-pollinating plants with duraweb® bags returned 47% more seeds per bud than parchment bags, and 38% more than muslin. And hybrid plants in our bags gave an average of 57% more seeds than those in muslin.

Using pollen tents to increase seed yield in fescue (Festuca) and ryegrass (Lolium)

Controlled breeding of grasses for seed production often depends on physically distant nurseries and isolation plots to prevent wind pollination. At the Noble Research Institute in Oklahoma, USA, we tested pollination control tents made with duraweb® as an alternative approach.

The results showed a 36% increase in seed yield from plants in tents compared with a control, indicating that they’re a useful tool for controlling grass pollination. The microclimate inside the tents helped keep the seeds disease-free and plentiful.

Improving pinecone survival in the loblolly pine (Pinus taeda)

Breeders of loblolly pines use pollination control bags to isolate the female strobili (cones) from outside pollen, ensuring only introduced pollen will reach them. Our bags were trialled against the industry standard Kraft paper bags, comparing cone survival rates and suitability for mass production of seed. The study spanned nine orchard sites across the southeastern USA.

Cones from duraweb® bags were more than three times more likely to survive than the ones in Kraft bags. The duraweb® bags were also significantly faster to install and remove than the Kraft bag types with wires, reducing labour time by 35%.

Proving the pollination-prevention power of our tents for sugarbeet (Beta vulgaris L.)

We worked with Lion Seeds in Essex, UK, to research the pollen-proofing abilities of pollination control tents made with three non-woven duraweb® fabrics and one woven fabric with a less porous construction. We wanted to find out if a more breathable, light-permeable construction would still be effective in preventing unwanted pollination.

The study showed that trial duraweb® fabrics performed just as well as the traditional duraweb® tents and that our more open-pored fabric still effectively blocks pollen while letting light, air and moisture through. In a follow-on study, molecular fingerprinting confirmed the genetic purity of the beet seed from the duraweb® tents.

Ongoing innovation

Our research and innovation journey doesn’t stop here. We’re continually trailing, testing, and evolving our products to support the needs of seed producers and plant breeders worldwide with our duraweb® materials.

Keep up with the latest research by signing up to our newsletter.